|

|

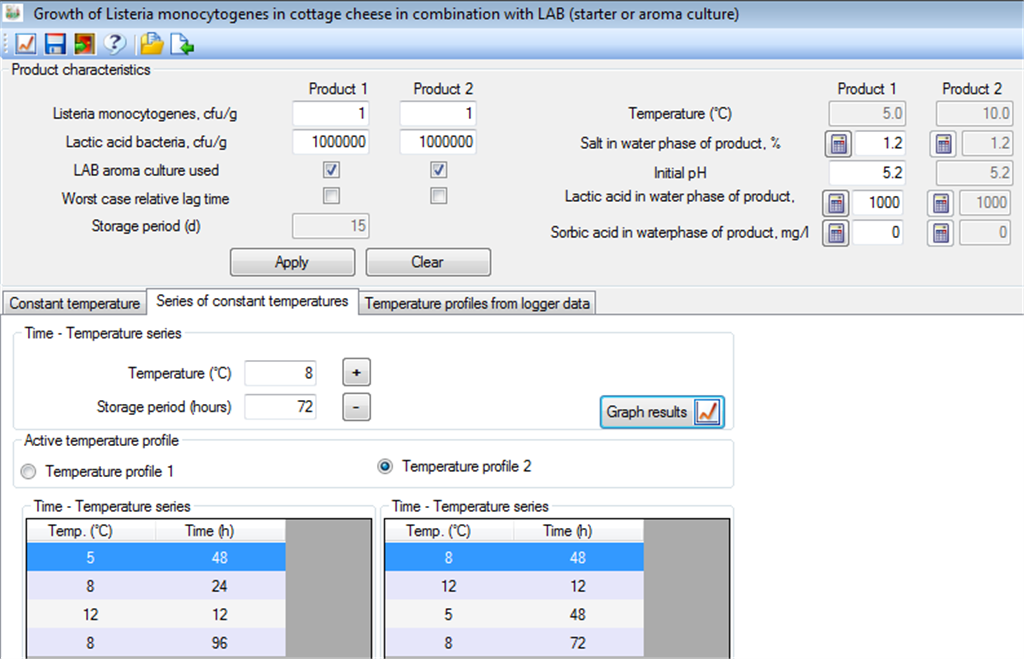

| Model | Listeria monocytogenes and mesophilic lactic acid bacteria (LAB) in cottage cheese |

| References |

Østergaard, N.B., Eklöw, A., Dalgaard, P. (2014).

Modelling the

effect of lactic acid bacteria from starter- and aroma culture on growth of

Listeria monocytogenes in cottage cheese.

Int. J. Food Microbiol.

188, 15-25.

|

| Primary growth model | Logistic model with

delay and including interaction between

Listeria monocytogenes and LAB (Giménez

and Dalgaard, 2004) |

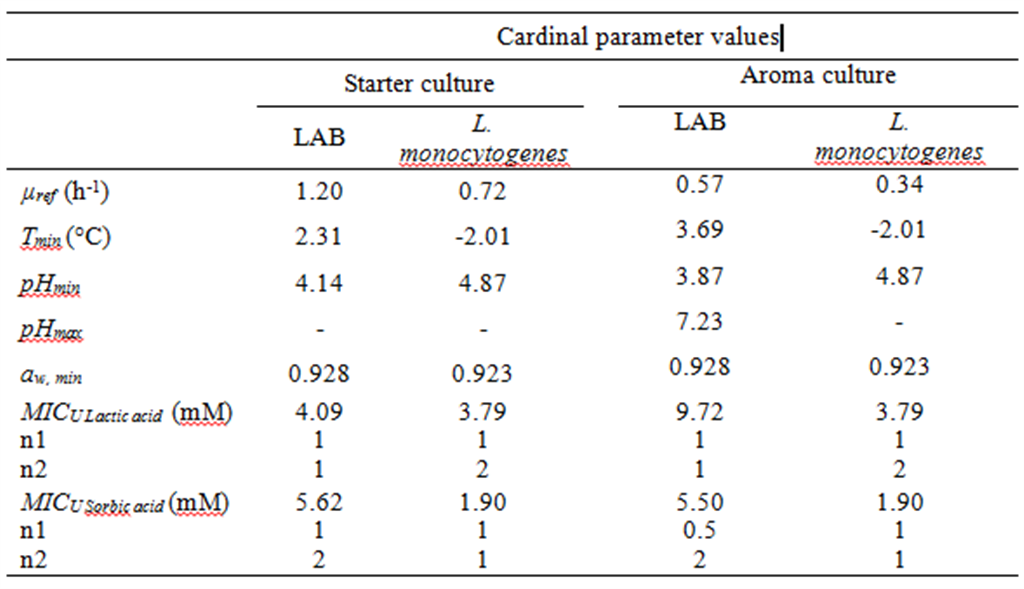

| Secondary growth model | Simplified cardinal parameter type model |

| Environmental parameters in model | Temperature,

pH, water

phase salt/aw, lactic

acid and sorbic acid |

| Product validation studies | Cottage cheese with

fresh or with cultured cream dressing (Østergaard et al. 2014) |

| Range of applicability | Temperature (5-15°C),

pH (5.0 - 5.5), water phase salt (0-2%), lactic acid (0-2500 ppm in water

phase)

and sorbic acid (0-1000 ppm in water phase). |

|

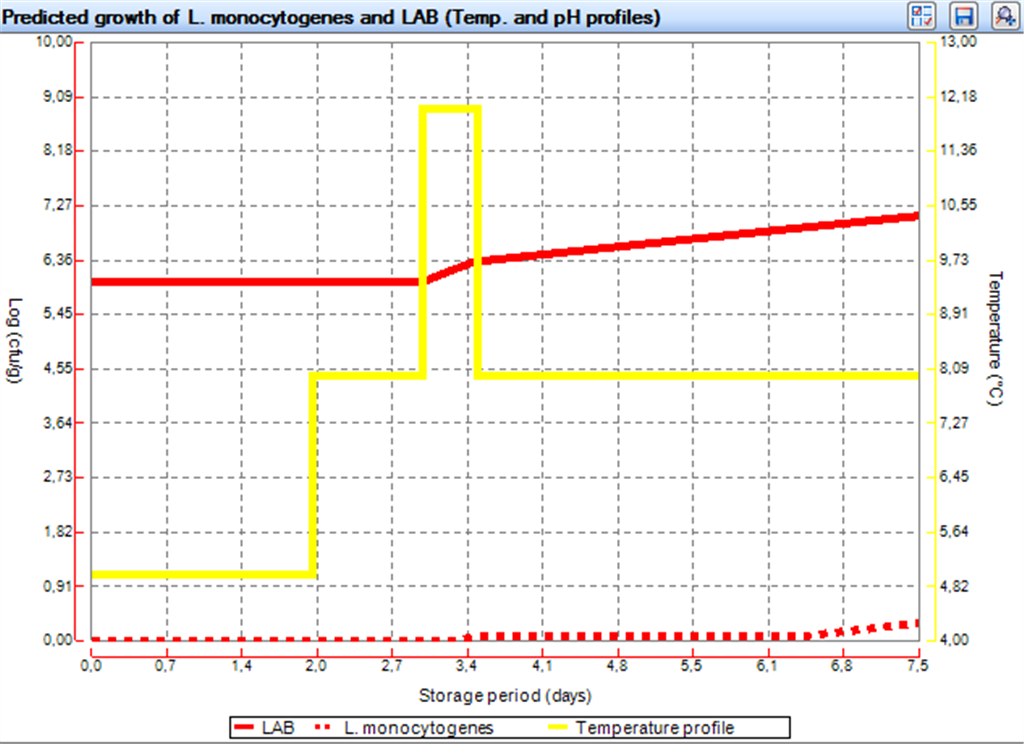

This product specific set of models in FSSP is developed

to predict

the simultaneous growth of L. monocytogenes and lactic acid bacteria

(LAB) in

cottage cheese (Fig. 1). Potential growth of L. monocytogenes

in cottage cheese is strongly influenced by the high concentration of

mesophilic LAB originating from the starter and aroma cultures used in processing of thís

fermented dairy product. FSSP includes specifiic models for LAB

and L. monocytogenes in cottage cheese with fresh/un-cultured

cream dressing and separate models for LAB and L. monocytogenes

in cottage cheese where the cream dressing is prepared by using an aroma culture (Lactococcus

lactis subsp. lactis biovar. diacetylactis) (See

Fig. 1 below). Information on the lag time of LAB and L. monocytogenes in cottage cheese is still limited. Therefore, these growth model in FSSP can be used with worst case lag times (fail safe predictions) or with average lag times (more realistic predictions for naturally contaminated products). FSSP predicts how high concentrations of LAB dampen and stops the growth of L. monocytogenes. This Jameson effect is important in order to accuratelty predict potential growth of L. monocytogenes and its influence on cottage cheese safety. As shown in Fig. 1 and Fig. 2 the FSSP software allow these predictions to be carried out conveniently for constant and variable temperature storage conditions. |

|

Fig. 1. The graph above shows the predicted growth of L. monocytogenes and LAB in cottage cheese with aroma culture and stored at 5°C or 10°C. As shown FSSP predicts the time needed for the concentrations of L. monocytogenes and LAB to increase under the selected product characteristics and storage conditions. Importantly, FSSP predicts the inhibiting effect of high concentrations of LAB on growth of L. monocytogenes (The Jameson effect). |

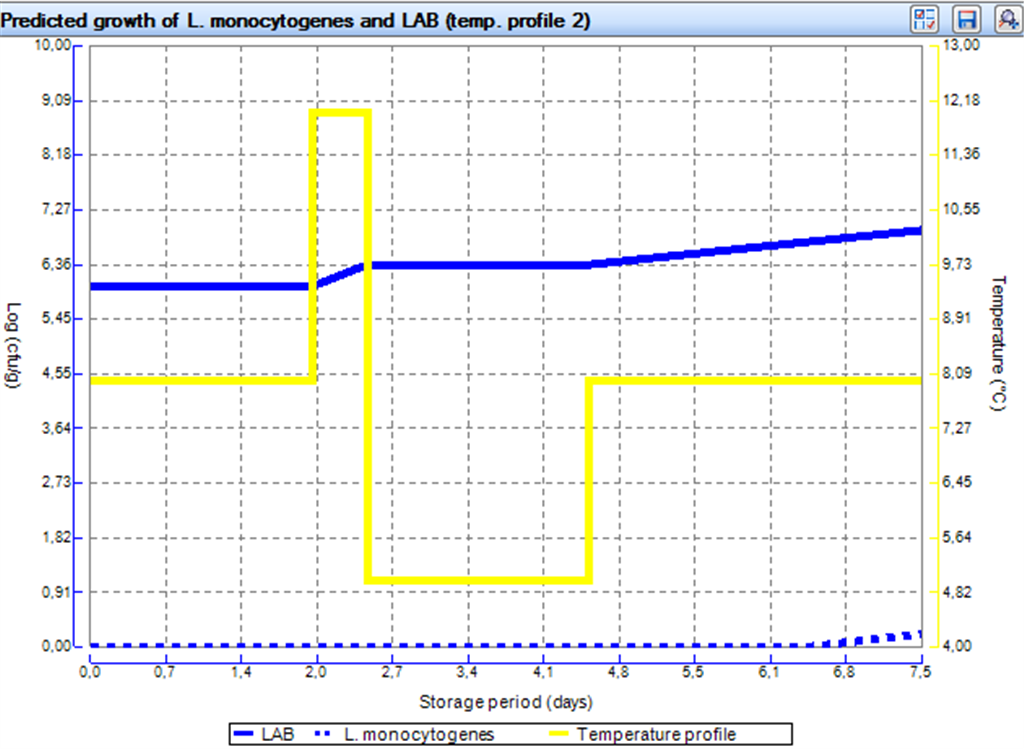

FSSP can predict growth of L. monocytogenes and LAB under changing temperature storage conditions. Simple temperature profiles can be typed in as 'Series of constant temperatures' whereas actual product temperature profiles most often are entered as 'Temperature profiles from data loggers' (Fig. 2).

|

|

Fig. 2. Effect of two simple temperature profiles on the predicted simultaneous growth of L. monocytogenes and LAB in cottage cheese with cultured cream dressing.. |

|

|

|

|

Eqn. 1. Primary model for simultaneous growth of Listeria monocytogenes and LAB according to the Jameson effect. tlag is the lag time and other model parameters are described in the text above. |

|

| Eqn. 2. Secondary model for growth of L. monocytogenes and LAB in cottage cheese. | |

|

|

|

|